Once the plan is clear, these services implement the required PLC and HMI changes, from small adjustments to complete platform migrations.

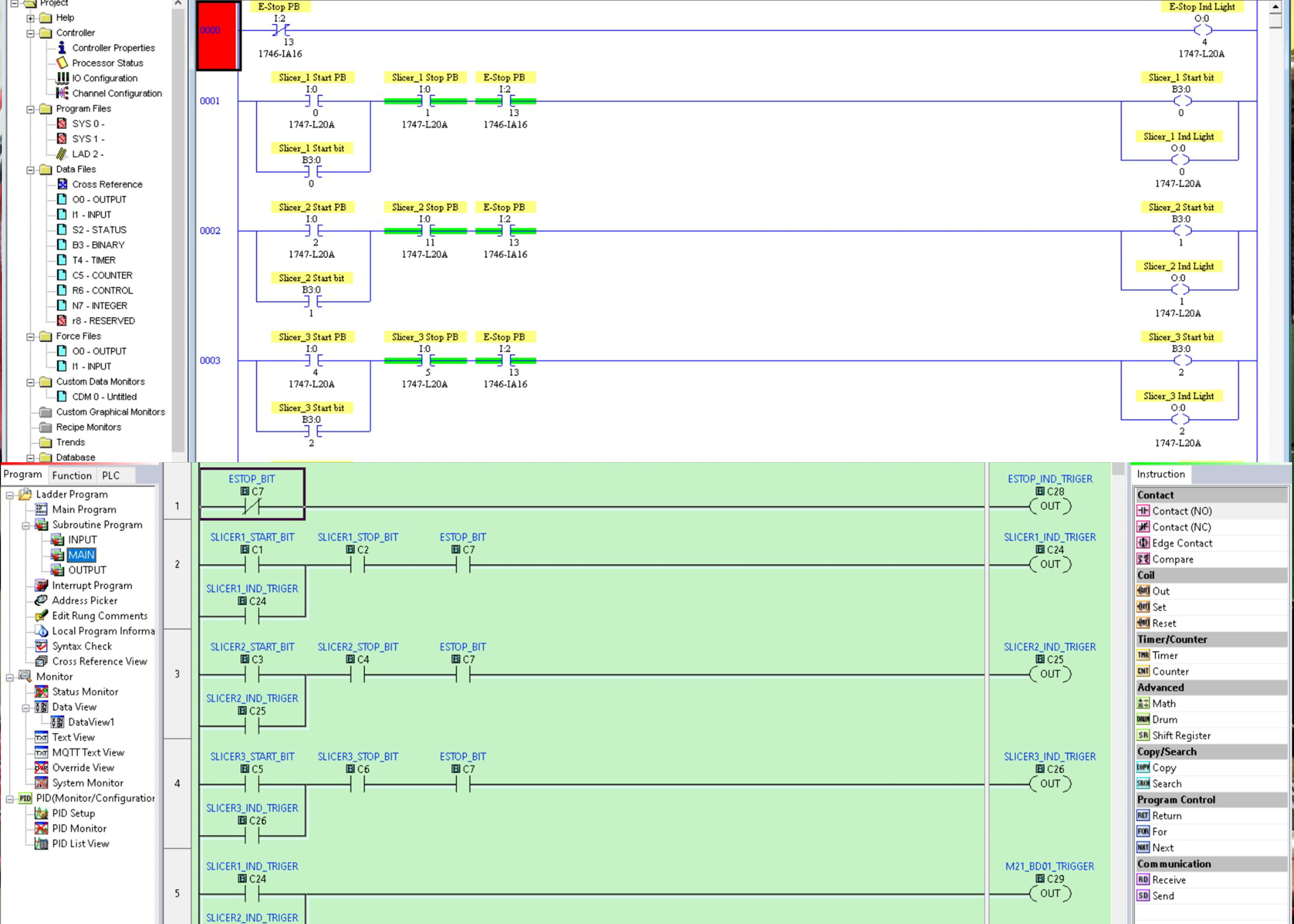

We completely rebuild your old PLC program on a modern controller using clean logic, clear tag names, comments, and offline testing.

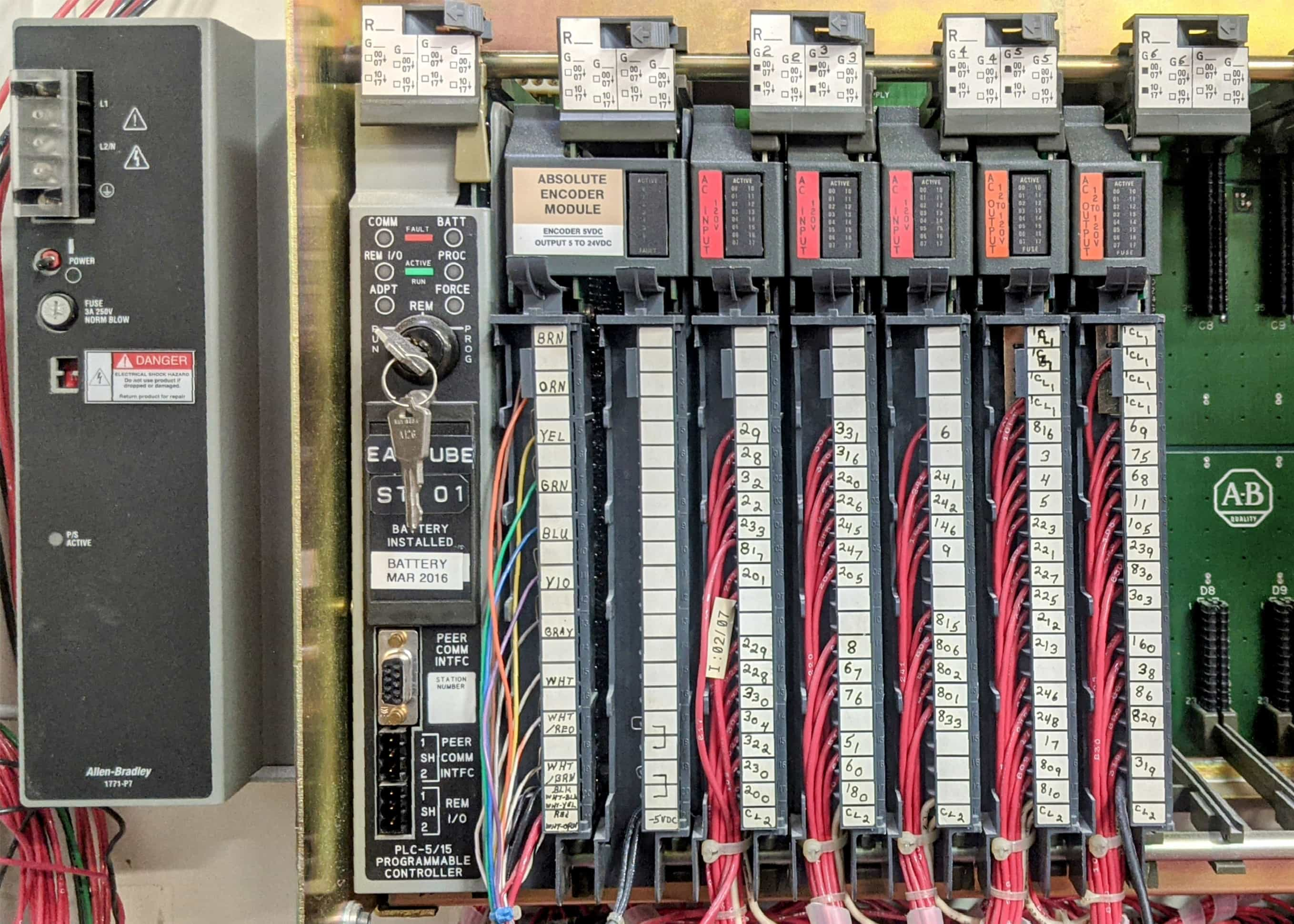

- New PLC program for the selected platform

- Structured tags and documentation

- Offline testing and verification

Ideal when original code is old or undocumented.

We design a new HMI application that is easy to read, shows the right information, and is fully aligned with the PLC tags and logic.

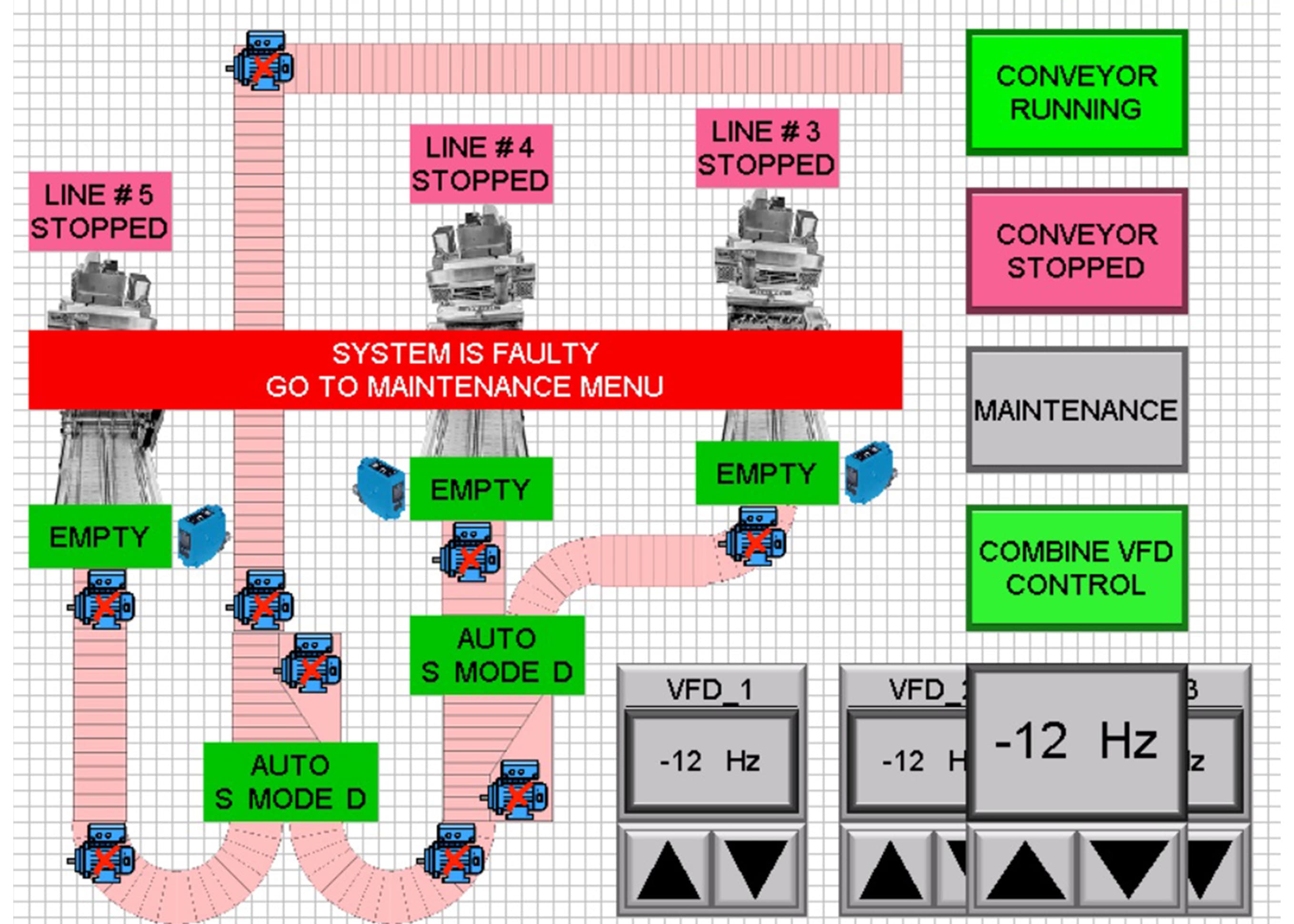

- New HMI screens and navigation

- Alarms, trends, and diagnostics

- Clean tag mapping and documentation

Improves operator clarity and maintenance.

We take responsibility for moving your system from old PLC and HMI hardware to a modern platform, including design, programming, testing, and commissioning support.

- PLC program rewrite

- HMI redesign

- Testing and on‑site/remote commissioning support

Best for major upgrades or platform changes.

We implement small improvements such as adding sensors or I/O, modifying sequences or interlocks, and adding alarms or extra screens.

- Scope agreed in advance

- Engineering, programming, and testing

- Updated documentation

Ideal when you want “tune‑ups” rather than full replacement.

We provide troubleshooting and support when control problems slow down or stop your production, either remotely or on‑site.

- Fault finding and diagnostics

- Temporary work‑arounds where needed

- Recommendations for permanent fixes

Supports maintenance teams during critical events.